A nozzle for every spray job

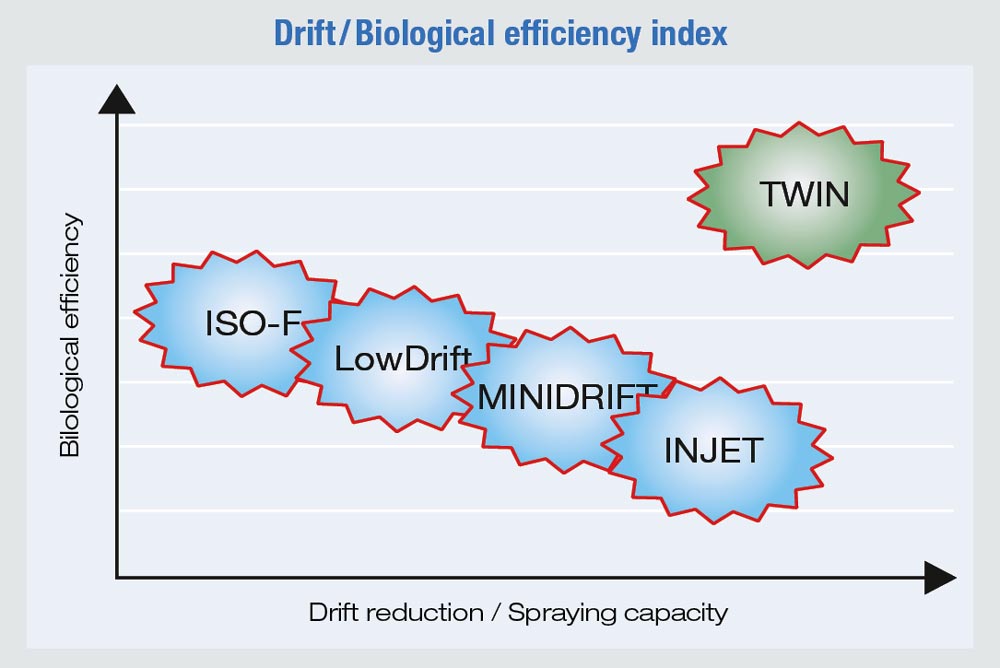

Choice of nozzle type and size may have to balance the need to ensure optimal biological effect with a consideration for wind drift, sprayer capacity – that influences field work rates – as well as forward speed.

Small droplets from STANDARD Flat Fan nozzles may offer an unsurpassed liquid distribution and an effective coverage of the target surface. HARDI TWIN sprayers can safely use these small standard nozzles even when weather conditions are not optimal.

The reduced number of very small droplets produced by LowDrift nozzles makes them less sensitive to wind. Therefore, they can be used on conventional sprayers under sub-optimal conditions. In particular, they are popular used when spraying lower water volumes.

MINIDRIFT and INJET nozzles mix air with the spray liquid to coarsen the atomisation. Drift is substantially reduced with these nozzles so that field delays – through too high wind speeds – are minimised and timing is improved. The biological advantage gained through this better field timing may mask the use of coarser sprays. Their use has become critical to conventional spraying practice which has to try and meet both environmental needs without risking the effectiveness of the product to be applied.

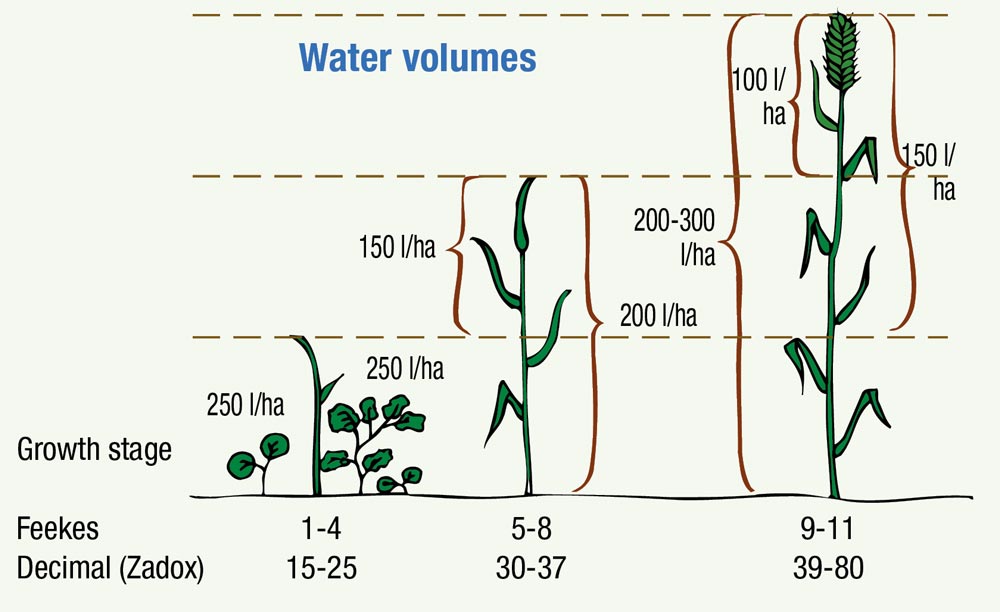

Water volume rate has a big influence

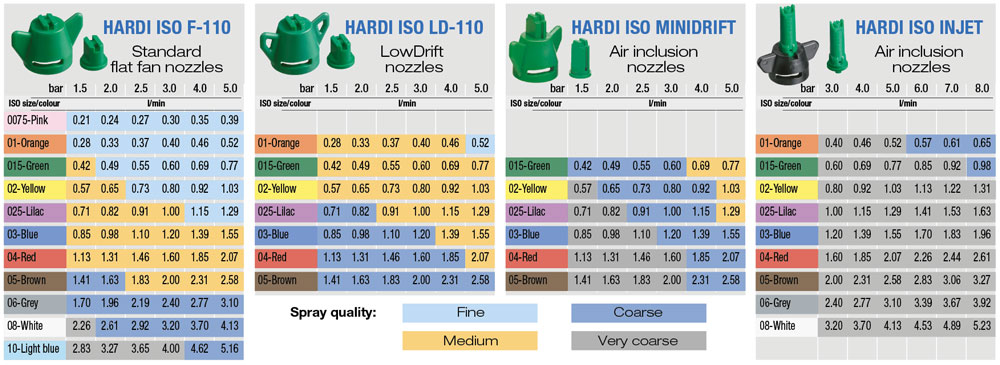

Your working capacity will largely depend on the water volume rate. Why? Low volume rates mean that less filling time and transport are required. In fact a volume rate reduction of 25% increases your capacity by more than 10%. A big difference even in the short term! You do, however, need to pick the right nozzle and speed for the job. Lower spray pressure alone will mean that both coverage and deposit are reduced. Note that the application rate of a nozzle should be approximately +/-40% of the medium flow at 3.25 bar.

What about droplet size?

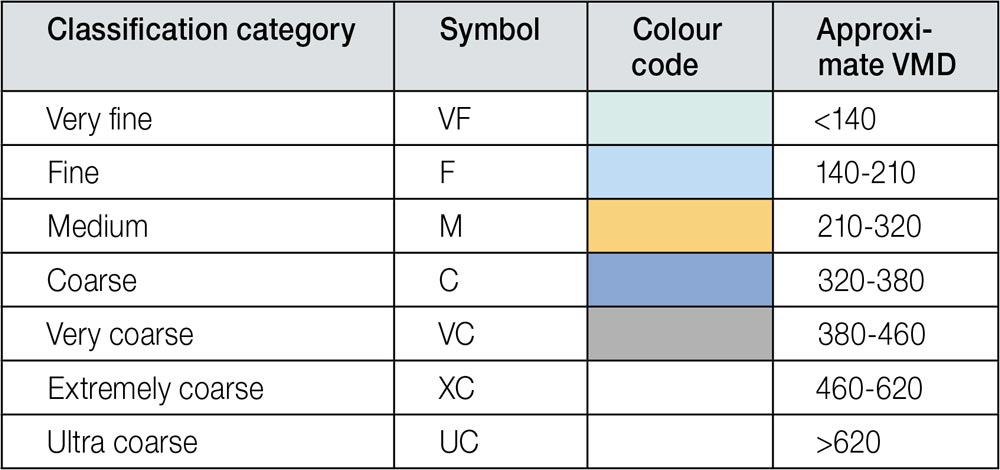

Droplet size is important, and your need will differ according to conditions and type of crop. HARDI nozzles follow BCPC/ASAE specifications with regard to droplet size classification. There are 7 size classifications but for most types of farming only “fine”, “medium”, “coarse” and “very coarse” are relevant. The challenge is that no nozzle will give you all spraying options and that is why you sometimes have to compromise.

The VMD data is belonging to the used measuring equipment. So the VMD data is only an estimate. The borders between the different categories are defined by a certain nozzle which is standardized in the ISO 25358. HARDI will only give the categories as the VMD as a single measurement is not useful for farmers as a decision tool. On the nozzle flow tables in this product guide is a seperate column to indicate the spray quality.

Make sure you have drift reduction nozzles

The new directive from EU states that a sprayer must be equipped with drift reduction nozzles. So if you have not already considered a MINIDRIFT nozzle, maybe now is the time. Standard equipment on a sprayer will soon be required anyway. Drift reduction nozzles work with very coarse droplets; this is the only way to reach a high drift reduction level.

Choosing nozzles

The tables on the next page can be used when choosing the right nozzle for a spray job. Important precondition for the tables:

• Always follow label recommendation for spray quality and volume rate – if nothing is stated, the tables on the next page can be used as a guideline.

• To minimise wind drift and maintain even liquid distribution, spraying pressure between 1.5 and 2.5 bar is recommended (INJET: 3 to 5 bar). Higher pressures with TWIN air assistance are also acceptable.

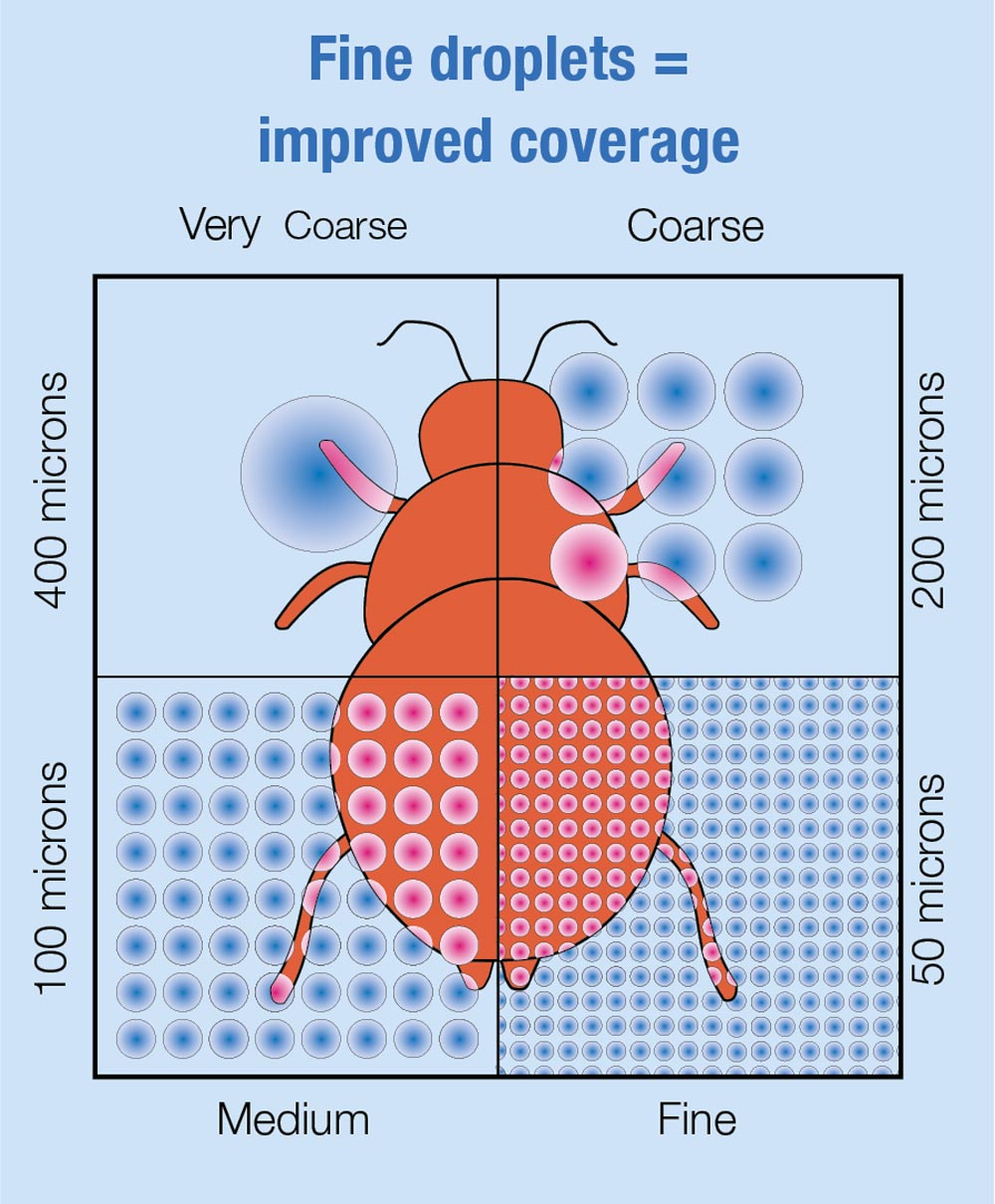

• Spraying against grass weeds or on other vertical targets – it is important to use a relative fine spray for a good coverage.

• Small dicot weeds need good coverage either through fine droplets or – if using a coarser spray – by compensating with a higher volume rate.

• Contact action mode needs finer droplets.

• Use medium sized droplets for chemicals that are transported in the plants

• For large dicot weeds – coarse atomisation can be used.

• Fungicide treatments are often less sensitive to spray quality; medium drops can be recommended. Remember that the volume rate must be adjusted to crop density and needs for penetration to more basal parts.

• Generally the water rate for conventional spraying should not be less than 150 l/ha and for TWIN not less than 80 – 100 l/ha for optimum efficacy at lower chemical doses.

• When mixing products or using products with more than one mode of action, adjust to the most demanding component of that product mix.

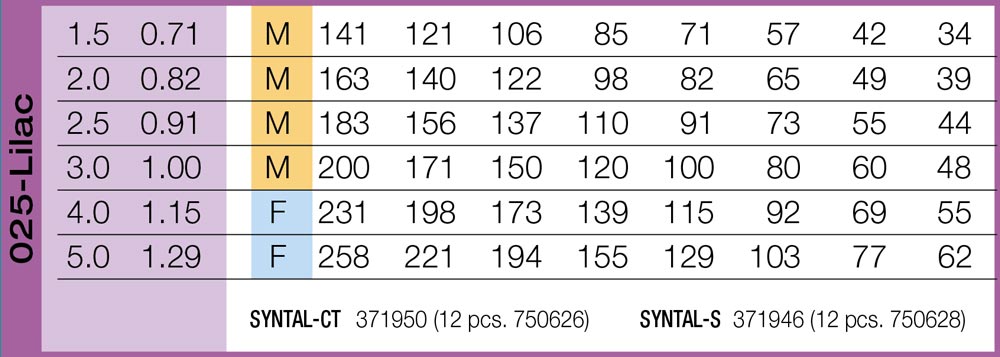

Spray quality and capacity for HARDI ISO 110° flat fan nozzles