Precise, dependable and accountable

HARDI has produced sprayers since 1957 - meeting the needs of all farmers and crops worldwide - a key goal that has demanded the world’s best nozzles.

Today the same basic HARDI philosophy promotes the efficient, effective and responsible plant care that ensures quality food production.

The nozzle can dominate the sprayer performance.

All of the sprayer components are important for safe and effective use, but it is the nozzle that can have the major influence on the performance of the crop protection product that it will apply.

The nozzle controls:

- The throughput [and therefore the dose]

- Quality of distribution

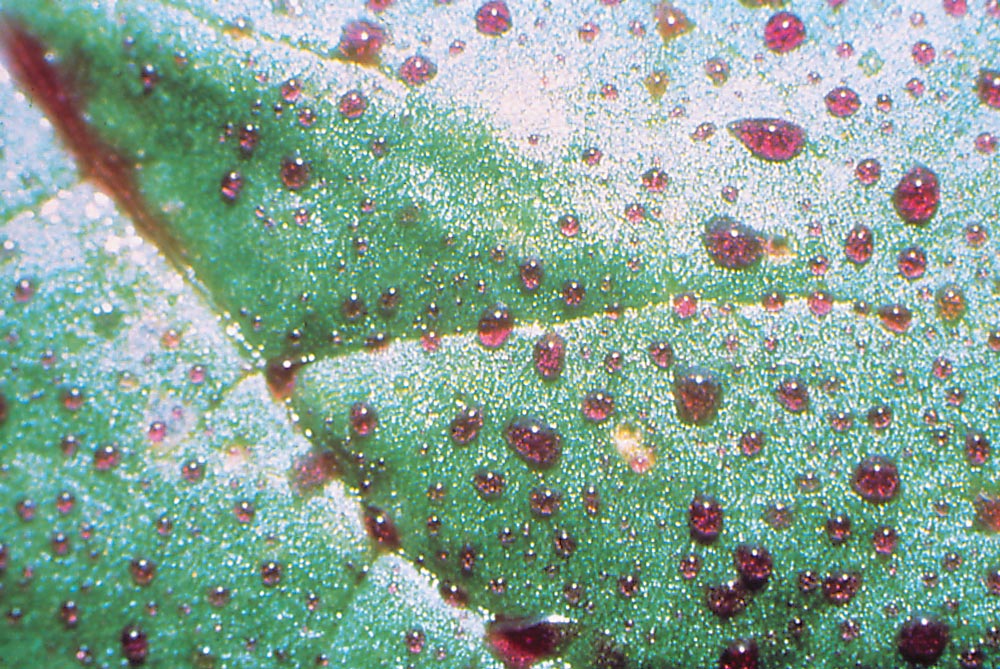

- Drop spectrum and coverage

- Distribution over the target

- Drop retention or reflection

- The degree of drift and downwind fall-out

All these functions are considered by HARDI to ensure that the spray liquid is deposited exactly where it is needed, in its most effective form, and is not wasted.

HARDI has combined both design and material selection to produce a range of nozzles that suit the broad demands of both crops and the vast array of agrochemical products available today. This has been the basis for HARDI’s worldwide success.

Close co-operation between farmers, advisers, chemical companies, independent and regulatory bodies with HARDI’s agronomists has been the backbone of this continuing success.

Quality in production ensures optimal field performance.

HARDI's modern production facilities and technical abilities have resulted in the superior precision and durability of HARDI nozzles.

Quality control includes not just laboratory measurements but the use of HARDI nozzles in the field under commercial conditions. Every drop of spray needs to be both accounted for - and documented - in order to ensure the quality of food delivered onto the dining table, and it meets the demands of the public today.

HARDI quality nozzles meet these increasing demands with world leading research and development.

The application of plant protection products to crops involves issues now, which go beyond traditional considerations such as economy and efficiency. Now nozzle choice and performance also relate to broad issues of drift such as airborne losses, downwind fall-out and deposits on non-target surfaces within the treated area itself. All of these issues need to be carefully considered.

HARDI is world leading in the understanding of concept of spray accountability and it is this knowledge that underpins its world leadership in today's spraying. Today, HARDI has developed the world’s largest ISO nozzle programmes for agriculture, horticulture [including most vegetables], viticulture as well as many more specialist needs. This nozzle guide will help you select the best nozzle for your needs, consider environmental aspects, and help you calibrate it for optimal use to ensure that you meet all of today’s needs when using crop protection products.